Let’s Decode the Different Types of Lathes Used in the Manufacturing Sector

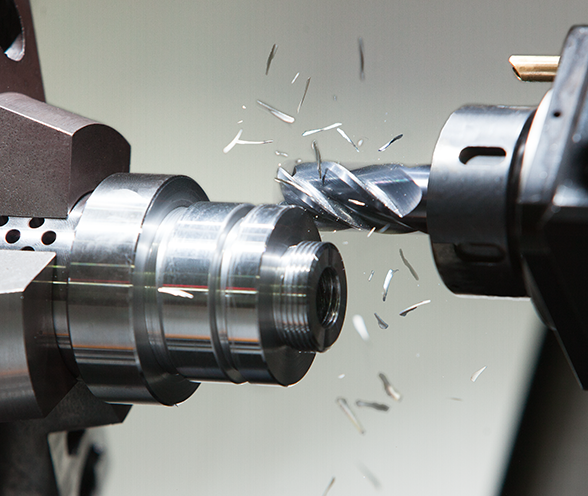

Let’s start from scratch. What are CNC lathes? A lathe is a machining tool that is used primarily for shaping metal or wood. It works by rotating the workpiece around a stationary cutting tool. The main use is to remove unwanted parts of the material, leaving behind a nicely shaped workpiece. The lathe is not just used for shaping or designing the metal. Now it has also become the most important tool to get the wood into shape. You name it and the wood art of any kind is possible with the machine. CNC lathe means the machine will run through software that is installed on a computer. This has numerous benefits such as, 1. Cut down on labor costs. 2. Reduce the possibility of errors. 3. Safety of the employees. 4. Accuracy and precision. 5. Speedy production. 6. Enhanced affordability. There are numerous types of CNC lathes that we will be discussing in this article. So, let’s get started. Types of CNC lathes in the Ma