8 Best Advantages of Custom Precision CNC Machine Services

In recent years, CNC machining services have grown in popularity. Many firms have benefited from these custom precision CNC machine services, which have helped them increase productivity, earnings, and gain a competitive advantage in their fields.

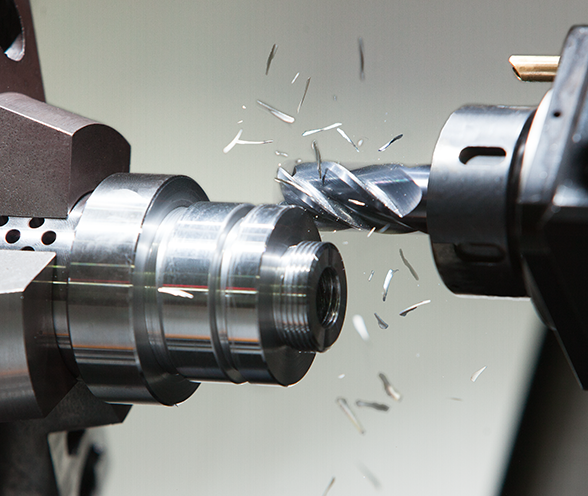

CNC or Computer Numerically Controlled machining is a production method in which industrial equipment and machinery are controlled by pre-programmed computer software. When compared to hand machining, this type of equipment can provide higher precision, increased production speeds, increased safety, increased efficiency, and most importantly, cost savings.

One of the benefits of custom CNC machining is that it can assist manufacturers in identifying obsolete parts. Customizing this part is straightforward with CNC machines, and you won't waste money or time looking for one. In this article, we will discuss key advantages of custom precision CNC machine services in detail.

What is Custom Machining?

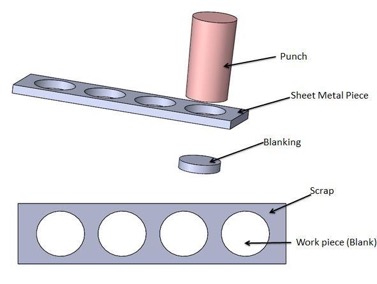

Custom machining is a sort of machining that entails the creation of pieces for a specific purpose or to a customer's specifications. To produce high-quality parts, it uses both manual and advanced machining equipment. For instance, CNC turning, CNC milling, and laser cutting machines are kinds of custom precision CNC machines.

The form, size, and type of material you'll be dealing with decide the custom precision CNC machine services required for a job. For some parts, manual lathes will suffice, but for others, a 5-axis CNC machine may be necessary. Almost every sector necessitates the use of customized CNC machine services. When a corporation need accurate CNC parts that are tough to produce using traditional methods, they will go for these custom precision CNC machine services.

Advantages of Custom Precision CNC Machine Services

1. Increased Productivity and Efficiency

Human error can be eliminated with precision CNC machines, which ensures consistent results. A CNC machine can work continuously without slowing down or stopping, whereas a plastic injection moulding machine will require an operator to complete repetitive operations.

G-code (a specific CNC equipment language) is used by custom precision CNC machine services to precisely control features such as speed, coordination, location, and feed rate. To control the complete operation, this machine simply requires a programmer at the end of the control.

2. Faster Turnarounds

Clients usually benefit from short lead times and speedy turnarounds due to improved software, cutting-edge machines, and superior tools, regardless of the intricacy of their project. When compared to other traditional machining procedures, custom precision CNC machine services use fewer machining operations to make the desired item. This enables you to complete tasks more quickly while maintaining a high level of accuracy.

Assume you want to cut a multi-stepped hole in a manifold. To cut this feature with traditional machining processes, you will need two ordinary drills of different sizes and a countersinking tool. A custom precision CNC machine, on the other hand, may create this feature in a single operation.

3. Improvement of the Quality of Parts

Custom precision CNC machines are noted for their completed products' precision and consistency. This is due to the fact that these machines can perform the same work over and over again. In hand machining, even if the operator is too meticulous, it also causes differences and inconsistencies in the quality of the product. You can acquire superior parts when you use custom precision CNC machine services

4. Lower Maintenance

Because the majority of today's precision CNC machining is done with the help of automation and robotics, manufacturing parts requires far less maintenance. It is no longer necessary for machinists to stop the operation in order to make minor modifications. Instead, individuals can move from one step to the next without experiencing any delays.

5. Higher Profits

You can’t boost profit margins by using manual labor instead of custom precision CNC machine services. Manual labor is only beneficial in the short run. You must rely on machining shops or centers that provide custom machining services if you want to achieve larger, long-term profit margins.

Precision CNC machining is the most accurate, fastest, and most efficient method of producing machining parts, which are often made of metal materials.

6. Precision and Consistency

These are the two most important objectives in every manufacturing project. These two requirements are easily accomplished because the machines are computer controlled. Every industrial operation is managed by software applications that allow consumers to specify their requirements. These software applications control the cutting and machining, ensuring precision and consistency in every product produced in a lot.

7. Better Safety

When manually-operated equipment is used in a variety of work settings, there is always a significant risk of injury. Such injuries will not only cost you money, but they will also leave you with a bad reputation in your sector.

Custom precision CNC machine services, on the other hand, significantly limit these alternatives. An operator only needs to supply initial inputs before walking away from the machine. Producers will be able to comply with user safety rules as a result of this.

8. Flexibility

Another advantage of custom precision CNC machine services is their flexibility. Because all the machines' tasks are pre-programmed, it's simple to make adjustments to them. By using a keypad, a machine operator can easily make a change. A machine can be programmed to make a different part with the same machine. This means that the same precision CNC machining services may be used to create a variety of unique parts and components.

Conclusion

Precision CNC machining is a method of cutting or drilling metal components with exceptional precision using a computer-controlled machine tool. As we can see that custom precision CNC machine services offer so many benefits. It has a better success rate than manually operated machines. Also, using custom precision CNC machine is much safer than custom precision CNC machine services

Manufacturers would be unable to obtain products on schedule if it weren't for personalized CNC machining, which saves them both time and money. More industries will seek for custom precision CNC machine services to obtain the results they want, which ultimately means that customized CNC machining will become more widespread.

Comments

Post a Comment