Let’s Decode the Different Types of Lathes Used in the Manufacturing Sector

Let’s start from scratch.

What are CNC lathes?

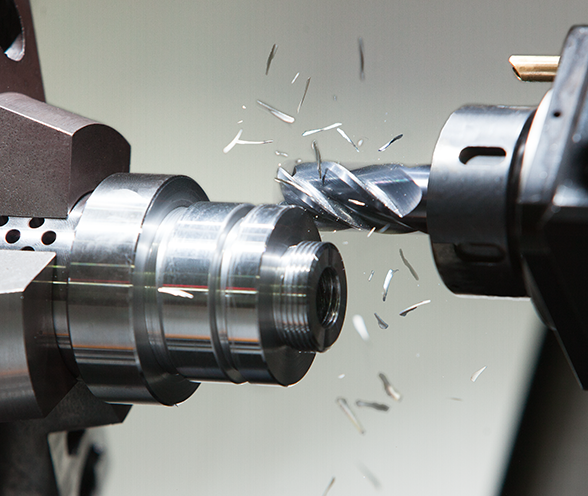

A lathe is a machining tool that is used primarily for shaping metal or wood. It works by rotating the workpiece around a stationary cutting tool. The main use is to remove unwanted parts of the material, leaving behind a nicely shaped workpiece.

The lathe is not just used for shaping or designing the metal. Now it has also become the most important tool to get the wood into shape. You name it and the wood art of any kind is possible with the machine.

CNC lathe means the machine will run through software that is installed on a computer. This has numerous benefits such as,

1. Cut

down on labor costs.

2. Reduce

the possibility of errors.

3. Safety

of the employees.

4. Accuracy

and precision.

5. Speedy

production.

6. Enhanced affordability.

There are numerous types of CNC lathes that we will be

discussing in this article. So, let’s get started.

Types of CNC lathes in the Manufacturing Industry

The standard CNC 2-Axis lathe

These lathes use O.D. tooling to extract material from the outside of the part and holders to remove material from the center. Generally, these Lathes have a single spindle, a turret, and a tailstock.

The length, diameter, and weight of the part being turned can make the overall capacity of the lathe vary. Depending on the age of the machine, cutting tools are held in an indexable tool post or a turret, allowing the machinist to change tools without removing them.

CNC 3-Axis Lathe

In addition to the X and Z axes found on a 2-axis CNC lathe, a 3-Axis lathe adds the C-axis with live tooling. This allows the cutting tool and workpiece to be angularly positioned so that milling, drilling, and tapping operations can be performed. It allows the machinist to add features to specific positions on the workpiece.

In these lathes, There are two configurations when mounting these holders to the turret – either on the outside edge of the turret or on the face of the turret. Live tool holders can also be offered in single spindle, dual spindle, or multi-spindle configurations.

Multi-Spindle

Another style of CNC Lathe is a multi-spindle/dual turret lathe, which has two spindles and two turrets. A multi-spindle lathe can have:

1. A dual

spindle, meaning two spindles of equal size and power

2. Or a sub-spindle, meaning that the spindle to the right is usually smaller in capacity and horsepower.

There are two turrets an upper and lower – one being used for the left spindle and the other for the right. They can include live tooling on either one or both of these turrets. Many times this style of lathe also includes a bar feed interface to allow automatic loading of the bar stock for higher production jobs.

Final Words

CNC lathe has numerous varieties to serve a plethora

of purposes in the manufacturing industry. They have brought a boost in the

production processes and that is why being widely used by manufacturers across

the globe.

Comments

Post a Comment