Why Choose CNC Machines Over Traditional Machines?

Traditional machines are losing their charm owing to the tech-driven CNC machines. These machines have brought a revolution in the manufacturing industry since their birth. They have helped manufacturers across the world by easing their manufacturing process to quite an extent.

Using this type of tech-savvy and traditional machine versus manual machining can result in enhanced accuracy, increased production speeds, enhanced safety, increased efficiency, and most of all cost savings.

Manufacturers who have been resisting adapting to these advancements in technology are forced to shut down their manufacturing firms amid lockdown as it was impossible to align with the change in the demand of the customers.

Numerous factors are responsible for the inclination of the people toward the CNC machines. Let’s discuss these options one by one.

Reason Manufacturers Choose CNC Machines over Traditional Ones

Ensure optimum level accuracy

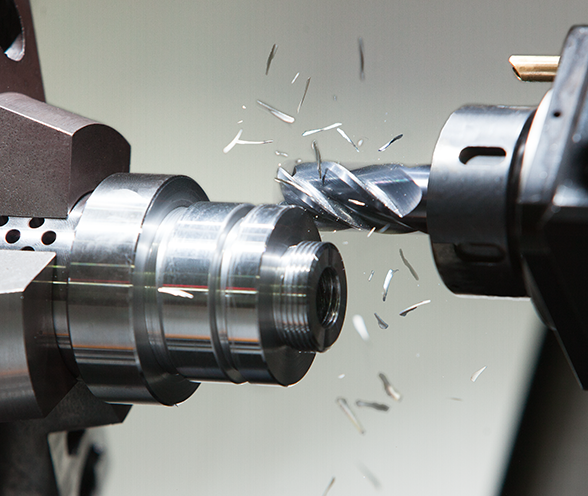

These machines require minimal to zero manual work and that is why offer 100% accuracy and precision. As we humans are bound to commit mistakes but machines are known for their perfection.

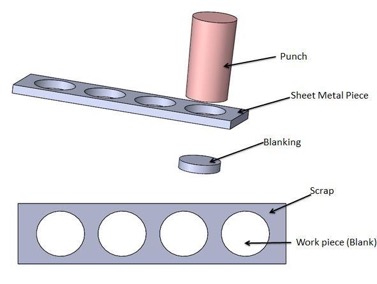

These machines are run by software that is stored in the computer and that is don’t demand manual operations for accomplishing manufacturing processes. The process is more precise than manual machining and can be repeated in the same manner over and over again.

Reduce manufacturing costs through labor cut

As said above, these machines are software-driven, and there is hardly any need for labor. This leads to a cut down in labor costs and enhances the profit percentage.

Even if you felt the need to hire a few workers, you don’t need to look for highly skilled ones who will ask for more pay. You can hire labor and can train them about the software within a week and they will be all set to operate these machines by themselves.

These machines don’t demand you to go through any top-notch training. On the other hand, traditional machining requires one operator per machine whereas CNC machines require fewer machine operators since one skilled operator can run several machines at one time.

Consume less time than the traditional ones

Computers are used to control the machines, the process is automated therefore increasing the speed and quality of manufacturing. Considering machines do not tire or need breaks makes it more efficient than manual machining.

In the manufacturing industry, time is money, and meeting the tight deadline of the customers is of utmost importance. Looking at this factor, it is important to invest in high-tech CNC machines.

These machines ensure safety

Gone are the days when accidents on manufacturing sites used to be common. With these advanced machines, workers’ safety has improved to quite an extent.

The process is more precise than manual machining and can be repeated in the same manner over and over again.

Final Words

The above-mentioned points are enough to justify the supremacy of CNC machines over traditional ones. These machines have improved the quality of manufacturing across the globe and have benefited many other industries as well.

Comments

Post a Comment