Let’s talk about the Applications and Benefits of Metal Blanking

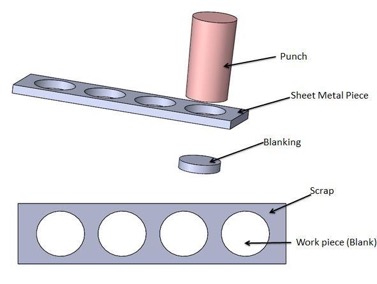

What is metal blanking?

Metal blanking is a steel manufacturing process in which a flat, geometric shape is created by feeding a coil of sheet metal into a press and die. In this process the blank is punched out from large metal sheet.

Blanking is most often performed with tools made from hardened steel or carbide, which work on metals like aluminum, carbon steel, stainless steel, and even plastic.

This process is a quick and cost-effective way to produce a large number of identical pieces.

Let’s talk about its process.

In this process, metal work-piece is removed from the primary metal strip or sheet when it is punched. The material that is removed is the new metal work-piece or blank.

Top Benefits of Metal Blanking in Manufacturing Processes

1. Quickest and hustle free process

Blanking process is one of the most simple, easy and fast processes in the manufacturing industry. It doesn’t demand much skilled labor or highly educated workers for its accomplishment. Machinery used for blanking ranges from simple punches and dies to sophisticated CNC machinery.

Blanking equipment can quickly be configured to end product specifications, and the process itself takes little time per part as it involves simply feeding the primary metal stock continuously into the blanking machine.

2. Have potential to bestow high quality products

These processes can be carried out in a way that makes it obvious to yield high quality end products. Technology has come a long way and which has made the process of blanking more efficient.

The straightforward process also allows you to construct materials to strict tolerances with little part-to-part variation, and technology has become so sophisticated that it can build multiple geometries using a single process.

3. Allow reusing and reduce wastage

Owing to the fact that the primary metal stock can be reused, blanking can help manufacturing firms reduce their material waste.

Due to this benefit, metal blanking is commonly used to mass produce components for industries such as aerospace and automobile manufacturing.

It’s also used for high-volume fabrication of parts for common household appliances.

4. A cost efficient process

The best part about blanking processes is that they don’t demand much investment. They can be done without burning a hole into your pocket.

As there is no need for skilled labor and only few men can handle it efficiently, it cuts down the labor cost tremendously. This is one of the major reasons behind its incredible popularity.

5. Abundance in application options

Blanking can be done on a plethora of materials like, carbon steel, stainless steel, and aluminum. Each material brings unique properties to the process.

For instance, stainless steel has low carbon content but a large amount of chromium, which ranges from 10% to 30% of the final material. This chromium content makes stainless steel highly resistant to corrosion and heat.

Summary

While looking at the above mentioned benefits of metal blanking, you can understand why this process is used in the manufacturing industry so widely.

Comments

Post a Comment