How to Enhance the Life of CNC Milling Machine Parts?

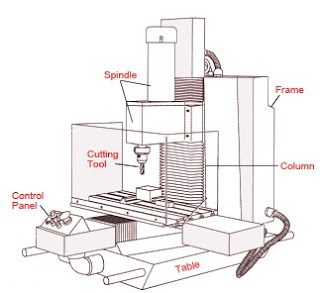

What is a CNC milling machine?

CNC Milling Machines are machine operated cutting tools that are programmed and managed by Computer Numerical Control (CNC) systems to accurately remove materials from a workpiece.

The end result of the machining process is a specific part or product that is created using a Computer Aided Design (CAD) software.

It has numerous benefits such as,

1. Requires few steps to produce parts, resulting in high efficiency

2. The process is more precise than manual machining and can be repeated in the same manner over and over again

3. Provides the ability to produce complex shapes with a high level of precision

4. Operates with advanced CAD software to produce outputs and multiple functions that cannot manually be replicated

5. Fully automated systems mean that the operator is not exposed to safety risks

It is vital to ensure the longevity of CNC milling machine parts, so that it stays with you for years down the lane while serving its purpose efficiently.

Ways to ensure optimum durability of CNC milling machine parts

1. Understand the needs of the machine

Yes, just like humans, machines have certain needs that must be fulfilled to enable it to yield best quality results. Being an owner it is your responsibility to do that.

You must keep it clean and avoid rough use. As it is governed by software in the computer, you need to take care of the software and computer working as well.

2. Pay attention towards the corrosion

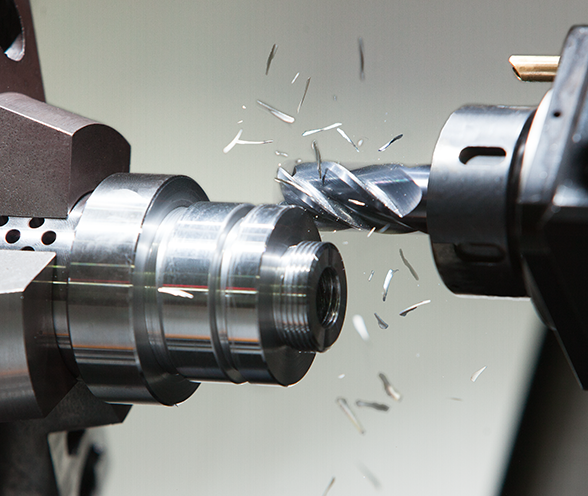

Surface finishes are not only for aesthetic purposes. Instead, they serve many other important purposes. One such purpose is corrosion resistance which helps a lot in maintaining the longevity of the machine’s parts.

Corrosion is a significant destroyer of metal parts and their surfaces. Rusts on metal surfaces reduce the quality of such components, and they won’t be able to perform their functions adequately.

Most of the metal machined surface finish examples target corrosion resistance. A correctly done machining surface finish ensures adequate protection of the metal. Therefore, you can be sure that it will last longer.

3. Keep an eye on its fluids and greasing

To make the machine longer, you need to take care of its fluids and greasing.

Fluids: CNC machines require adequate fluid levels, such as lube and hydraulic fluid. Working daily with your machines will give you a good baseline for how quickly the fluids need to be replenished.

When machines start using fluid at a higher rate, have your machines checked. Excessive fluid use can be a sign of problems.

Greasing: Grease is the smooth operator that keeps all the working parts moving and grooving. Not all machine shops check grease points each day, but we recommend looking at all moving parts for dry spots.

A quick shot of grease goes a long way to reducing unwanted wear.

Summary

To enable CNC milling machines to serve its purpose, it is vital to maintain the efficiency of CNC milling machine parts. The above points will help you immensely in this pursuit.

Comments

Post a Comment