A Guide to Industrial CNC Milling Machines & How Does it Work?

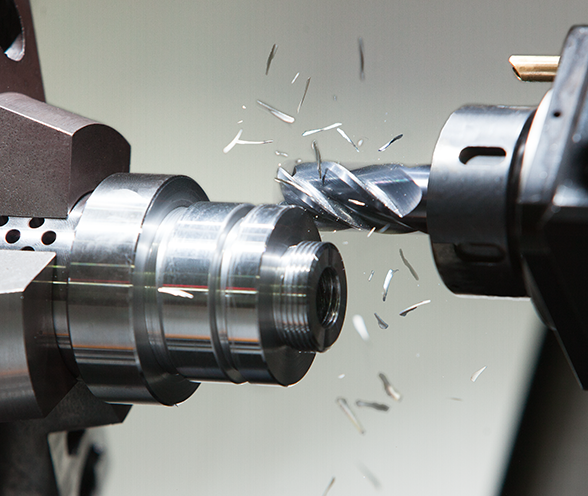

Milling is the removal of material with rotary cutters installed in a machine. An Industrial CNC milling machines is a computerized variant of milling in which machine operators program a machine to carry out milling operations automatically.

Industrial CNC milling machines encompasses a wide range of processes used by a variety of industries. These machine tools usually have a primary spindle and three linear axes for positioning and moving the part to be manufactured. We'll take a look at the main component of Industrial CNC milling machines and how they work.

How does an Industrial CNC milling machines Machine Work?

The object to be machined is clamped on top of the machine table in the fundamental principle of an Industrial CNC milling machines or CNC machining center. It might be clamped directly to the table or secured using a vice or fixture. The cutting tool and spindle are then positioned either vertically or horizontally.

The tool can reach multiple X-Y-Z positions on the work piece in this arrangement and begin cutting and shaping operations. As a result, the table can fix, mount, or move/position the work piece or part in a linear manner to the spindle with the cutting tool. This enables for the removal of material in the correct shape for the machined item.

What are the Main Components of an Industrial CNC milling machines?

Frame

The Industrial CNC milling machines’ frame is the fundamental component that supports it and serves to give it stability and rigidity. It usually includes a base and one or more detachable columns. The machine headstock, on which the main spindle is placed, is an important section of the frame.

Spindle

An Industrial CNC milling machines’ spindle can be thought of as its "heart." It usually consists of a spinning assembly as well as a tapered part where tool holders can be placed. The tool is frequently linked to the shaft of the spindle, usually via a tool holder.

Axes

An Industrial CNC milling machines often contain X, Y, and Z axes, as well as additional rotational axes, such as C, A, or B (subject to configuration). G-code in the CNC controller can be used to program these.

CNC Control Panel

This is the Industrial CNC milling machines’ nervous system. It houses the electronics that enable programming features to control the various cutting movements. A CNC monitor and programming buttons are located on the control panel, where data and codes can be entered. It usually has a manual mode as well.

Coolant Tank

During machining, most Industrial CNC milling machines centers contain a coolant tank to aid provide coolant to the cutting surface or spindle with tool. This prolongs the life of the machine and its components.

Conclusion

An Industrial CNC milling machines are machine-operated cutting tools that are programmed and managed by CNC systems to precisely remove materials from a workpiece. A specific item or product is developed utilizing Computer Aided Design (CAD) software as the end result of the machining process.

Comments

Post a Comment