Let’s talk about the Applications and Benefits of Metal Blanking

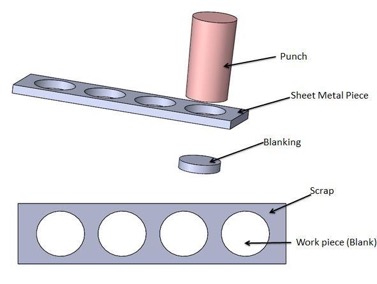

What is metal blanking? Metal blanking is a steel manufacturing process in which a flat, geometric shape is created by feeding a coil of sheet metal into a press and die. In this process the blank is punched out from large metal sheet. Blanking is most often performed with tools made from hardened steel or carbide, which work on metals like aluminum, carbon steel, stainless steel, and even plastic. This process is a quick and cost-effective way to produce a large number of identical pieces. What is the metal blanking process? Let’s talk about its process. In this process, metal work-piece is removed from the primary metal strip or sheet when it is punched. The material that is removed is the new metal work-piece or blank. Top Benefits of Metal Blanking in Manufacturing Processes 1. Quickest and hustle free process Blanking process is one of the most simple, easy and fast processes in the manufacturing industry. It doesn’t dema...